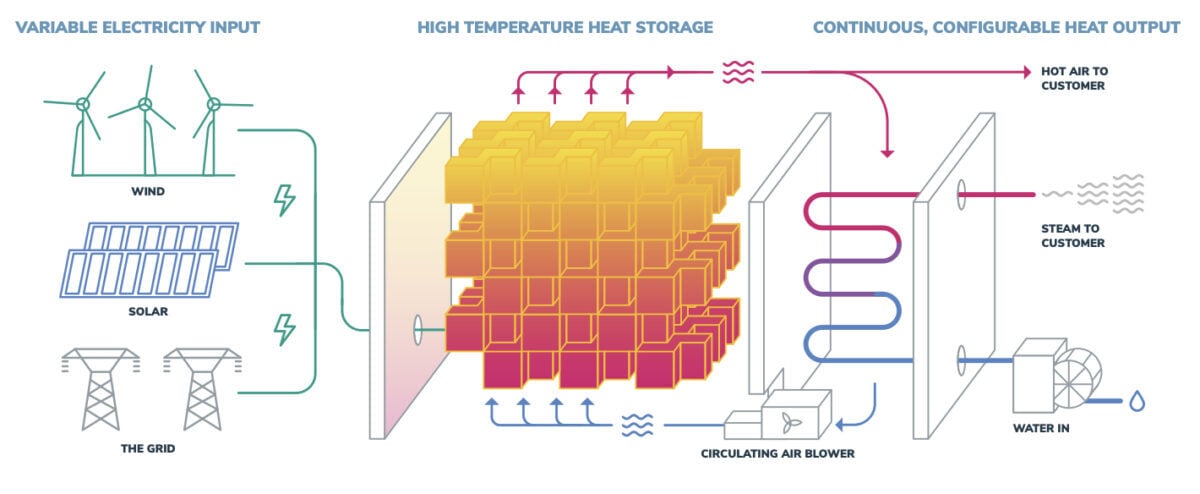

Firebrick systems powered by renewable energy could be used for up to 90% of industrial process heat applications, the Stanford study says. Meeting that demand in the U.S. would require firebrick system capacity of 2.6 TWh, with a peak discharge rate of 170 GW.

I would think molten metal would be more effective for this, molten sodium or lead or something? Maybe some kind of Tin/Lead eutectic like old solder?

Firebricks just seem inefficient somehow, particularly since the heat isn’t going to be uniform, while molten metals or salts can circulate and convect the heat more efficiently than… air.

The main advantage of using what is basically dirt is that it’s dirt cheap. You need a metric fuckton of this stuff so the cheaper the material, the better. Also, molten metal is difficult to handle.

Fine, but given … everything, it seems like you could do some smaller system with channels in the bricks for conduction, it’s the hot air that bothers me, that’s not great to try to use for conducting energy everywhere, you get turbulent effects.

How else would you heat up a huge pile of bricks? This is for industrial applications or grid scale heating systems. They basically all use hot air.

They use hot air warmed by gas burners.

Since we’re using electricity here, and this was mentioned in the study linked elsewhere, they used ceramic heaters.

Their previous study also goes into efficiency and cost.

One of the main advantages of firebricks is their low cost.

Ok, they’re claiming 98% rt efficiency.

I don’t think we have 98% rt efficiency in anything, ever. That’s miraculous. Batteries are around 92% at best? Pumped hydro is 85% or so.

That even sounds high for raw carnot efficiency.

I mean, if so, wow, that’s awesome, and I don’t really doubt their 1% daily decay, that seems attainable.

But 98% rt? I’m still skeptical.

I am not a material scientist, but I would wonder if molten metals would radiate too much heat to the environment causing an efficiency loss