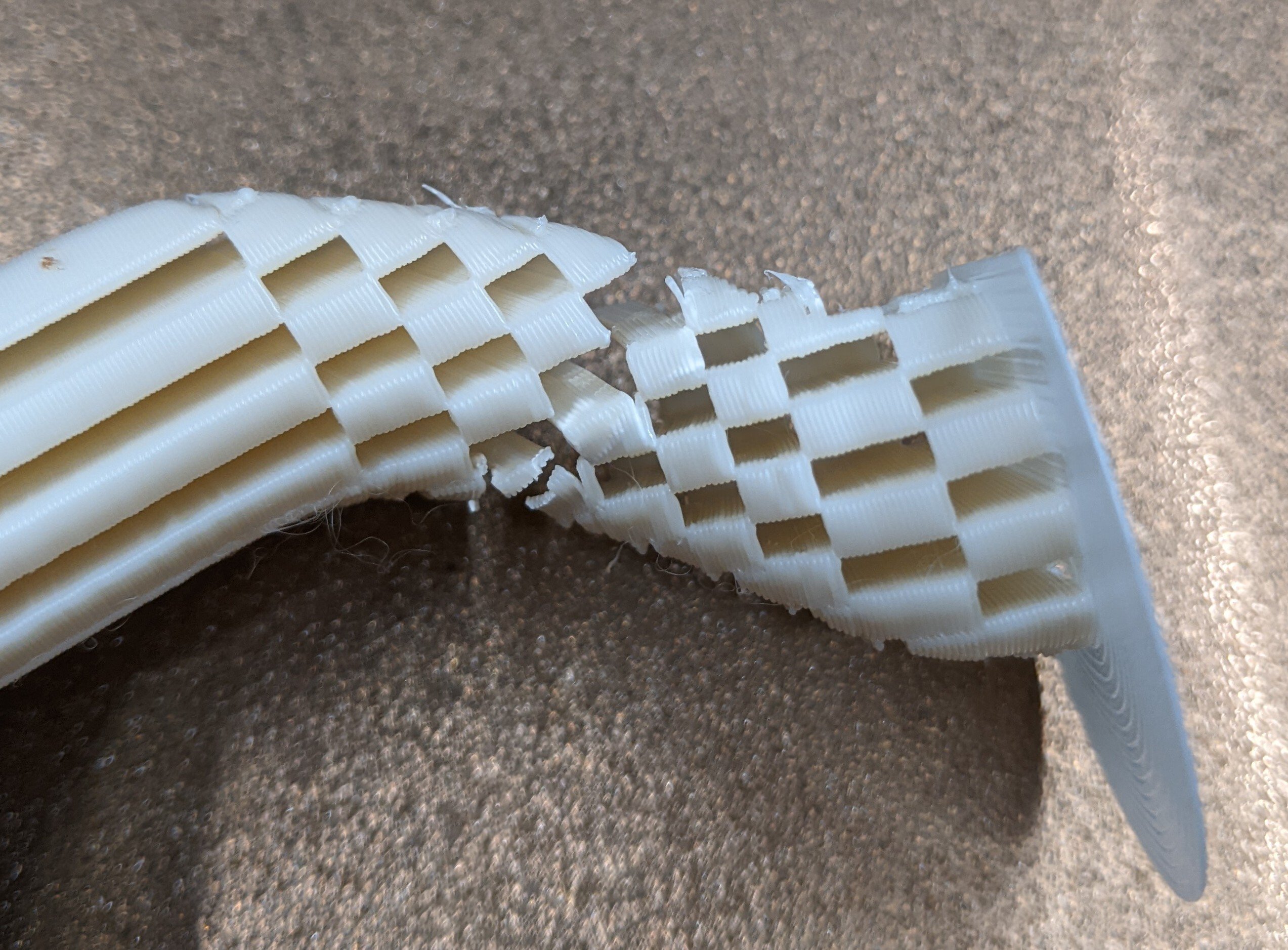

At least so far. The first go round had the nozzle crash into the tree support, resulting in a layer shift. The good news is that the print stayed very firmly stuck to the bed.

I’ve reset, lowered my extrusion multiplier a smidge, switched to a more traditional support pattern, and am going for it again. Wish me luck!

That’s a fire hazard (in case you weren’t already considering it)

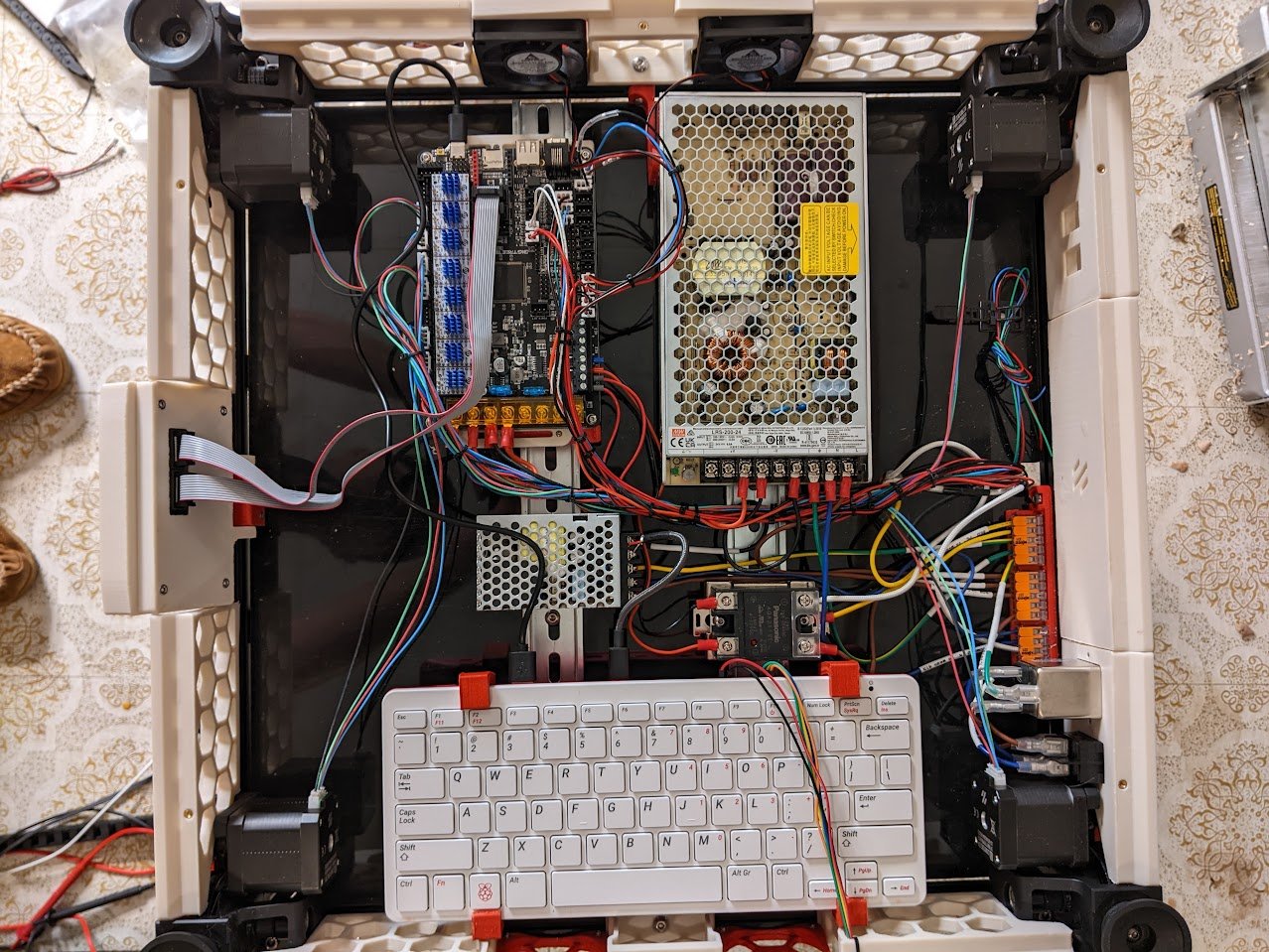

The printer is a a Voron 2.4 running klipper with a chamber thermistor, controlled bed fans, and an exhaust fan so it will do a decent job regulating it’s temperature. The electronics are outside the chamber and there are acrylic panels under the blanket and hoodies. Should it come to it, klipper has thermal runaway protection. There’s also a smoke alarm right next to the printer. I suspect this will be a pretty uneventful print.

I let the printer heat soak for an hour and a half before giving it a go and barely cracked 60 °C, so all should be well. This is a Voron, so the electronics are out of the chamber, have a cooling fan, etc.

Other than looking somewhat janky, this isn’t that different than the insulated panels I’ll be swapping on to replace the current acrylic panels.

None of this stops the risk of fire.

Once a fire starts, the printer turning off won’t magically stop the fire from continuing to grow.

Printers can fail in all manner of ways.

Also, you should have a venting solution of printing ASA.

It’s pretty cheap to get a proper fire resistant heat cover for a printer.

Just get an emergency “space blanket”, they’re often only a couple bucks and quite good, but very fire resistant.

I guess I’m not clear what the source of ignition would be? The chamber is fairly well temperature controlled, so it’s not likely that something inside will overheat. The cloth that’s draped over outside of the printer can’t come into contact with any hot bits thanks to acrylic panels. The chamber itself is currently sitting at 59 C after the print has been going for 10 hours (plus 1.5 hours of preheat before that).

Agree on venting, I need to duct my exhaust fan to the outside.

A space blanket is a good idea. I have a few lying around and will add one. Bonus points for being a radiant barrier (eg should help get things warmer again). I’m surprised that mylar will help prevent the spread of fires.

All the electronics inside are very much capable of combustion.

Your power supply inside the printer body for example can very much fail and burst into flames.

And tbh it’s not that uncommon for that to happen with 3d printers. They’re often made with very cheap parts and prone to cheap work on the inside bits.

Add on how much of a high wattage load they meed to handle for extended periods of time and yeah, sometimes the inner wiring bursts into flames and the whole thing goes up.

I always recommend keeping a cheap lil smoke alarm directly overhead any 3d printer, seriously. Those fuckers can very much spontaneously burst into flames lol

Well, you’ve just decommissioned my printer until I’ve changed the smoke detectors batteries

The electronics are housed in a (reasonably) sealed airspace below the print bed and have two fans blowing across them. Here’s a link to CAD/STLs/some pictures: https://vorondesign.com/voron2.4. If you want to poke around GitHub, you can do so here: https://github.com/VoronDesign/Voron-2. No printer is perfect, but Vorons are fairly well thought out and I didn’t skimp out on components when I was sourcing parts. All wiring inside the enclosure is either PTFE or silicone insulated.

Here’s what it looks like underneath:

I always recommend keeping a cheap lil smoke alarm directly overhead any 3d printer, seriously

Totally covered.

I do get where you are coming from with outlining all of the precautions you have taken, and I agree that the print is 99% likely to go just as fine as all your other ones, but there’s no amount of planning or prepping you can do that will change the fact that putting a pile of flammable articles over a massive source of thermal energy is indeed a fire hazard.

This is coming from someone with a very not ideal setup that does not have great fire safety precautions. (It’s inside a wooden hutch with a curtain draped over it for heat retention… 😬) I understand that my setup is dangerous, and I accept those risks. You aren’t making yourself any safer in denying your own.

EVGA had PSUs that blew up. Samsung is still too afraid to put ultra fast charging in their phones because they were blowing up. AMD GPUs were starting fires like 10 years ago. Just because you bought nice parts, doesn’t mean you aren’t dumping a ton of power through very delicate and fragile components that at any second could decide to kill themselves and everyone around them.

Not trying to say you shouldn’t do this because it’s your setup and you know it better than people online, just that you should keep in consideration when making these decisions that none of the things you’ve explained will matter if a large capacitor goes pop, and if it’s under a pile of sweaters you’ll probably have a much bigger problem to deal with than you would have otherwise.

Ultimately, if the printer is going to go up in flames the source of those flames won’t originate at the cloth draped over the acrylic enclosure. The chamber barely cracked 60 °C, which is well below what smaller Vorons, especially V0s, will hit with only acrylic panels. Yay lots of surface area I guess.

It will be very interesting to see how everyone reacts (or doesn’t) to some “better looking” insulation. The sources of ignition won’t be any different, but I bet that people will be much more comfortable looking at insulated ACM panels that were built for purpose.

It’s called the ADHD mod

I’m looking into printing with ASA eventually - have you tried skirts on an ASA print? (Not sure what other slicers call it - it’s a wall that is printed around the print to shield drafts)

I don’t have an enclosure on my delta so was considering that as an alternative.

Yes, I’ve done skirts. At a certain print size/aspect ratio it doesn’t really matter though - the parts are going to want to warp without a warm enclosure. If you have great first layer adhesion it will just take your build plate with it. You’ll find a picture of that happening on this printer if you look through my post history.

Smaller parts in x/y and round corners will help prevent warping.

I printed all the parts for my Voron using an i3 clone under a cardboard box. I doubt that “chamber” got very warm, but it was enough for success.

What the holy hell is this nonsense?

You guys will do anything to keep from buying a good printer won’t you?

I’ve done 21 hours prints in my damp cold basement without issue.

You guys make me feel so competent haha.

Imagine feeling so confident to indirectly call Voron a bad printer and tell people how to spend money.

Go get yoursel something to work on instead of mocking other for their temporary solutions.

ASA and ABS are warp prone and this is an 11" / ~275mm wide print that’s equally tall 🤷

The build volume of my printer means lots of surface area for the acrylic enclosure, which in turn makes it hard for me to exceed a 50°C chamber temp, despite 4x bed fans.

The next print, with normal supports, pulled the bed off the magnetic build plate. Insulation eliminated warping and let me pull off the print.

I do agree that a “nicer” enclosure is the preferred method. I have zero issues with PETG at this size. I’ve never tried PLA on this printer, but it should be fine too.