Really good article with lots of tips that helped me improve my designs. Highly recommended.

Super helpful! Bookmarking it for the ol’ troubleshooting toolbox. 🤓

Keep up the great work, neighbor! 🖖🏼

That is a fantastic article, thank you for sharing it.

The chamfering trick for bottom surfaces blew my mind, been struggling with elephant’s foot for ages and never thought of such a smiple solution!

A+ treatment of theory and practice perfectly blended

This is a very sharp article. Think I first saw it on Hackaday. I should be using the checklist more often. If there is to be a 3D print bible like Machinery’s Handbook, this article is foundational.

In particular, chamfers and fillets and their relationship to strength by reducing stress risers is often missed on amateur designs.

I need to look at crush ribs and ribs for screws/bolts more.

The idea of a sphere being the most efficent shape is counterintuitive when most mechanical design is inherited from subtractive manufacturing. Also, speed holes reducing strength and increasing material usage is wild. These are powerful ideas that are going to cause almost a philosophical change in manufacturing. It’s going to take decades. Absolutely mind-blowing stuff when you really think about it.

DFM, in general, is a woefully underappreciated aspect of engineering. One of the great things about 3D printing is that the designer is generally forced to eat their own dog food.

MEs should recieve more education about DFM. 3D printing would be an easy way to force them to understand the difficulty poor design causes. Of course, DFM for subtractive is a larger and more complex subject, but printing would at least teach the lesson with a little sting.

Like others have already said, this article is a good collection of tricks/principles/examples. There are also lots of links out to other resources that cover the various items in more detail.

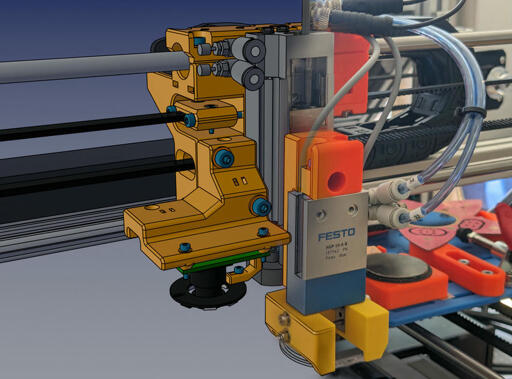

But I haven’t seen anyone mention how awesome that head image is! Take a closer look if you didn’t at first. I’d love to see an animation that wipes from design to completed piece.