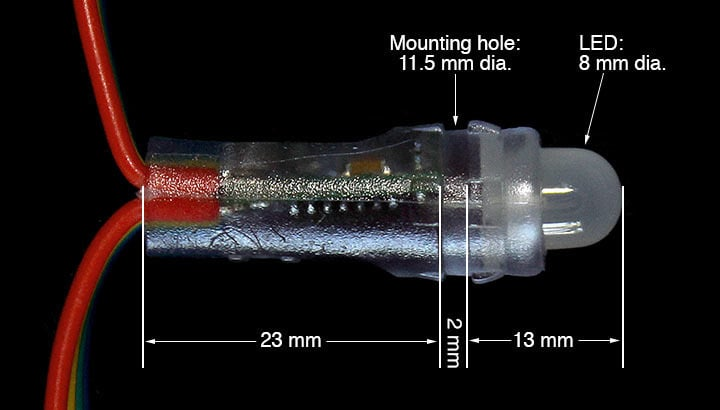

I’m in the process of replacing all my single-color christmas lights with addressable RGB LEDs, but the 12mm “bullet” form factor of them is different from the traditional incandescent mini lights, the 5mm wide angle LEDs, etc.:

You’d think they’d make C6/7/9 bulb covers that attach to them, but I have yet to find any for sale, anywhere. As such, I want to 3D print some, along with 12mm bullet pixel-sized replacements for my snowflake lights:

What’s some good filament I can get that will be reasonably clear and stay that way (without yellowing or getting too brittle) for several years’ worth of Christmas seasons, despite UV/rain/cold exposure?

(Bonus question: anybody know a good way to model the facets in those “strawberry” lights? The C7 bulbs on Thingiverse, such as this one, are all smooth, LOL.)

Edit: by the way, to be clear (pun intended): I don’t need optical clarity like the lens guy; scattering the light is fine. (In fact, doing that on purpose is kind of the point of modeling a faceted C7 bulb instead of a smooth one.) I just want to make sure that whatever part of the filament that doesn’t manage to be transparent is white, not tinted some dingy color.

I do happen to have some Inland “natural” PLA laying around and did a test print in that. It’s not too bad – only a little bit yellow at the wall thickness I’m using – but I fear for how it will hold up over time.

I just want to thank you for your comment even if it didn’t quite answer my question (which is, I assume, why you deleted it). I’m very much a CAD guy, not an artistic 3D modeling guy, so the Blender approach is a total mystery to me and I appreciate you causing me to think about it.

My approach would be something more like creating the profile of the bulb using a bezier curve (b-spline) revolving it to make it a solid, figuring out some way to apply the facets (that’s the part I need help with), and then offsetting it to make it a hollow thin wall shell.

It’s those facets that have me stumped: I think I’ve figured out that probably the way they do it in the real world is to carve spiral cross-hatched V-grooves into the mold they cast the things from (basically like knurling), so the result is the negative impression with raised edges and sunken centers instead of pointy pyramids. But how the Hell do I do that to a bezier-curved surface in a parametric CSG modeller like OpenSCAD or FreeCAD?!

(I wonder if posting this reply to a deleted comment will work?)

Yeah I didn’t realize you were after a specific style of faceting until I posted the comment and scrolled back up. I’m sure there’s an easy way to do it in blender, I’m just not quite sure how… I’ll let you know if I figure it out! The method would be subdividing each face of the icosphere in three, with a point at the center of each triangle and cutting lines from the existing corners to it, I’m just not sure how to do it automatically. Once you have it divided like that, easy enough to grab those new center points and scale them out to make your triangle facets

Here’s the result the deleted comment yields

With a basic bevel

Took a quick crack at doing it by hand, subdiving an icosphere in that specific way and copying it around.

Definitely a bit time consuming but not too bad for that many faces. I imagine scaling it up would make finding an automated solution more important though. That was maybe 10 minutes of work? not bad

scaling it and solidifying yields this

Step by step:

Basic icosphere

Subdivided the edges and connected to opposing corners to find the middle of the triangle

Cut the last edge in and dissolved unnecessary edges

Repeated for each level, then duplicated and rotated 5 times to make the sphere out of these divided faces (mirrored on the z axis to save half the work)

Selecting all those midpoints with a side on xray view

From there just scaling them out to make the pyramids

If you want to do that in OpenSCAD, I’d look into how a pineapple gets cut, and then try to emulate that. I’ve dabbled with openscad but never got super far in it, so not sure what’s possible with revolves and splines and the like